High Erosion Resistant Cobalt Based Alloy Vs Tungsten Carbide Saw Tips

Tungsten Carbide Welding Inserts have enough toughness shall be guaranteed by the maximum allowable size of the tips and by using a rather strong steel grade and heat treatment. Tungsten carbide inserts havea secure fixation which is guaranteed by the flutes of the tool holders and the quality in welding.

|

ISO Code |

Grade |

Physical and mechanical properties |

Applications recommended |

||

|

Density g/cm3 |

Hardness HRA(HV) |

TRS (Mpa) |

|||

|

K05 |

YG3 |

15.0 |

90.5 |

1300 |

Suitable for finishing of cast iron and nonferrous metal. |

|

K10 |

YG6X |

14.8 |

91 |

1560 |

The finishing& semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

|

YG6A |

14.7 |

91.5 |

1510 |

||

|

K15 |

YG6 |

14.9 |

89.5 |

1670 |

Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

|

K20 |

YG8 |

14.6 |

89.0 |

1840 |

|

|

M10 |

YW1 |

13 |

91 |

1290 |

Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel |

|

YW3 |

12.9 |

92 |

1390 |

||

|

YW4 |

12.3 |

92 |

1390 |

||

|

M20 |

YW2 |

12.9 |

90.5 |

1460 |

The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the maching of railway wheel hubs. |

|

P10 |

YT05 |

12.6 |

92.5 |

1260 |

Suitable for the finishing and semi-finishing if steel and cast steel with a moderate feed rate and a rather high cutting speed. |

|

YT15 |

11.3 |

91.0 |

1300 |

||

|

P20 |

YS14 |

11.4 |

91.5 |

1550 |

Suitable for the finishing and semi-finishing of steel and cast steel.YS25 is specially used for the milling of steel and cast steel. |

|

YT14 |

11.4 |

90.5 |

1400 |

||

|

YS25 |

13.0 |

90.5 |

1780 |

||

|

P30 |

YT5 |

12.8 |

89.5 |

1560 |

Suitable for the heavy duty rough turning of steel and cast steel with big feed rate at a medium and low speed under unfavorable working conditions. |

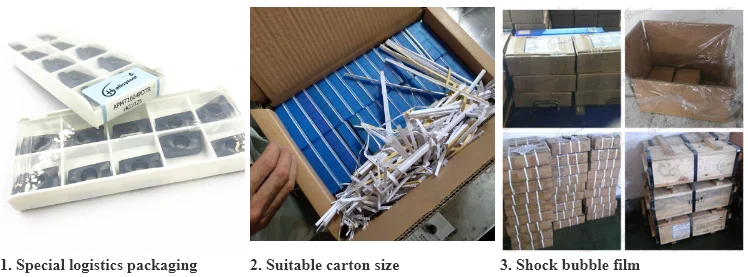

A. standard packaging

1).Plastic box with foam inside and carton outside.

2).The carton has foam inside and carton outside.

3).Inner box/inner packing material, outer plywood box (heavy duty product).

Customizable packaging: according to customer requirements for special packaging.

Q1: Are you a factory or a trading company?

A: We are a factory. We have been focusing on Tungsten Carbide for over 20 years.

Q2:What is your principle for the samples?

A: We offer free samples if you are willing to pay the freight.

Q3:What is your delivery time?

A: Generally it is 5 to 7 days if your required goods are in stock, otherwise it takes 20 to 30 days when there is no stock.

Q4:Do you have any test reports or certificates?

A: Yes, we can offer certificate of ISO9000:2008, we also report our test results for your reference.

Q5: Do you provide after-sale service?

A: Yes. So if you find any problem after using our cutting tools, please do not hesitate to tell us, we’ll help you to solve it as soon as possible. Your any feedback to products is our way to improvement

Q6: What should I do before contacting?

A: You can provide specific dimensions or drawings, and tell us the quantity of each item, and your application of this item. Other special requirements is also available.

Q7:How to contact us?

A: Directly contact us from inquiry, or by whatsapp or wechat. Other ways you can also provide us.