Tungsten Carbide Mining Tips,Tungsten Carbide Button,Tungsten Carbide Insert Buttons

Product Description

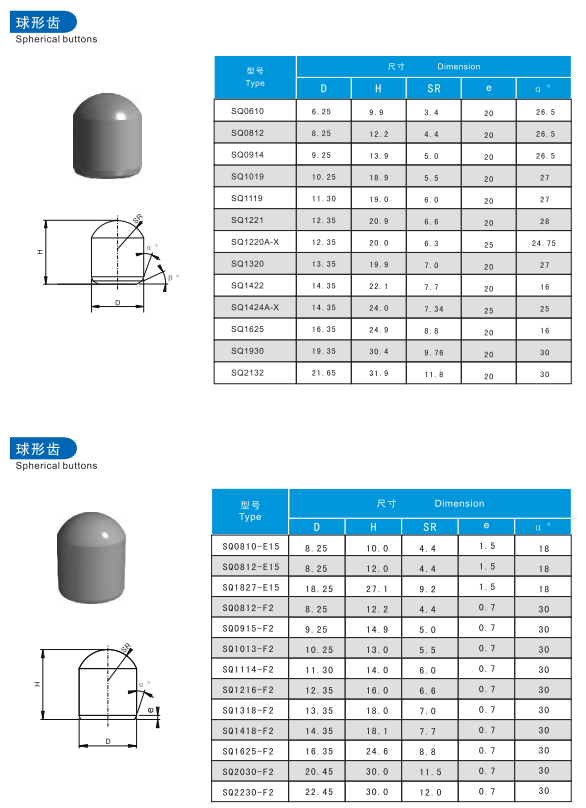

As for spherical tungsten carbide buttons, below are the general features for your reference. For more details of specific type, please inform us.

1. Made of special and excellent raw material, have more stable properties, increase the yield of complete drilling and mining bit substantially;

2. Extra grain size available, have higher impact resistance and lower hot crack and breakage;

3. Ground and tumbled, ensuring uniform of dimension and surface smoothness, easier to mount;

4. HIP sintered, increase the strength substantially therefore extend service time; full range of types and specifications are available.

Grade & Application

|

Grade |

Hardness HRA |

TRS N/ mm² |

Density g/ cm³ |

Applications recommended |

|

YK06 |

90 |

2200 |

14.9 |

It is mainly used for medium or small hard alloy ball teeth, insert the cone drilling and impact drill, and get into the soft and medium hard rock. |

|

JK05 |

89.5 |

2400 |

14.8 |

|

|

JK10 |

89 |

2200 |

14.4 |

It can be used for geological exploration and drilling tools and coal mining can be used as soft rock, coal seam and non-silicified rock drilling tools. |

|

YG8C |

88.5 |

2500 |

14.7 |

|

|

YG9C |

87.5 |

2600 |

14.5 |

|

|

YG11C |

87 |

2600 |

14.4 |

It is suitable for drilling tools. |

|

YK20 |

86.5 |

2600 |

14.4 |

|

|

YK25 |

87 |

2600 |

14.4 |

|

|

YG13C |

86 |

2800 |

14.2 |

Suitable for hard alloy coal cutting teeth, turning teeth, tunneling, drilling in hard rock and hard rock. |

|

YK30 |

86.5 |

2800 |

14.35 |

|

|

YK40 |

86 |

2800 |

14.35 |

|

|

YG11CN |

88 |

2500 |

14.4 |

With high hardness and wear resistance, it is suitable for snow and snow shovel snow. |

|

ZS10 |

87 |

2800 |

14.35 |

High strength, good toughness and wear resistance is a bit poor, is suitable for crushing a diameter of less than 50 mm hard sandstone, quartzite, tightly silicide dolomite, silicide quartzite, iron ore, diorite, granite, sandstone, basalt stones, pebbles, etc. |

|

ZS20 |

88 |

2600 |

14.45 |

The hardness and wear-resisting are generally applicable to the crushing diameter of less than 45mm metamorphic sandstone, granite porphyry, granite, common limestone, granite porphyry, open-pit granite, dolomite, magnetite and so on. |

|

ZS30 |

89 |

2500 |

14.6 |

High hardness, good abrasion resistance, suitable for hard and hard granite with crushing diameter less than 40mm, amphibolite, siliceous slate, copper pyrite, marble, sandstone, etc. |

|

ZS40 |

90 |

2400 |

14.7 |

High hardness, good wear resistance, suitable for crushing diameter less than 40mm limestone, sandstone, sandy shale, poor iron ore, silicified clay sandstone, etc. |

Reference Drawing

1. Direct factory sale;

2. Reasonable price;

3. Good wear resistance;

4. Longer service life;

5. OEM service available;

6. Short and on time delivery

Company Information:

Zhuzhou HGtool Tungsten Carbide Co., Ltd. was established on 2015 and located in Zhuzhou, Hunan province, specializing in the research and development, production, sales and technical services of new materials.We manufacture all kind of tungsten carbide products such as Carbide Inserts, Carbide Tips,Carbide Strips & Plates, Carbide Composite Rods ,Carbide Crushed Grits and any other customized product.

Who We Serve:

Q&A

|

Q1: Are you a factory or a trading company? |

|

A: We are a factory. We have been focusing on Tungsten Carbide for over 30 years. |

|

Q2:What is your delivery time? |

|

A: Generally it is 5 to 7 days if your required goods are in stock, otherwise it takes 20 to 30 days when there is no stock. |

|

Q3:Do you have any test reports or certificates? |

|

A: Yes, we can offer certificate of ISO9000:2008, we also report our test results for your reference. |

|

Q4: Do you provide after-sale service? |

|

A: Yes. So if you find any problem after using our cutting tools, please do not hesitate to tell us, we’ll help you to solve it as soon as possible. Your any feedback to products is our way to improvement. |